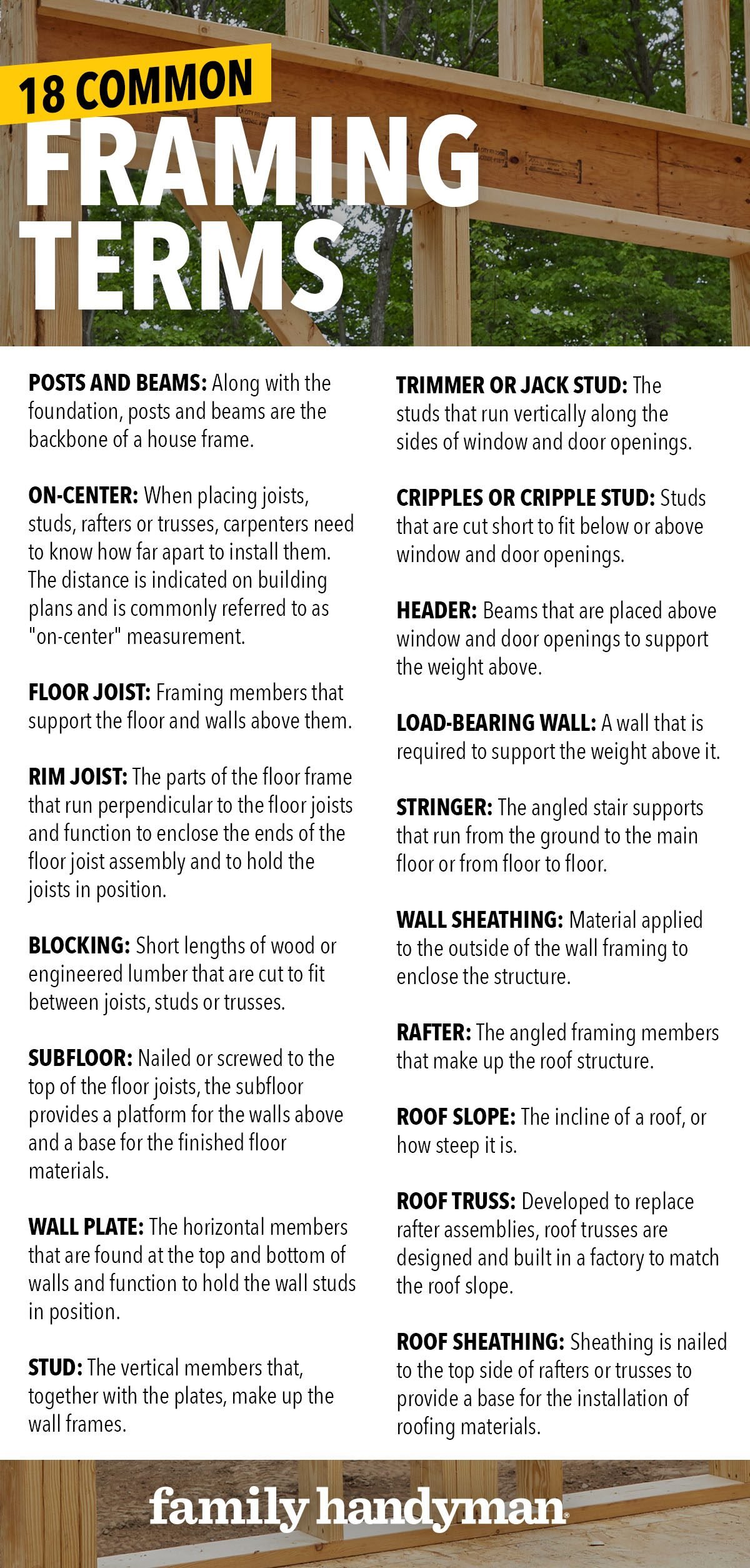

Want to learn about house framing, but find the terminology confusing? Read this handy guide to common house framing terms.

Posts and Beams

Along with the foundation, posts and beams are the backbone of a house frame. A beam is a horizontal support and a post is a vertical support. Together they are used to provide support for the framing in areas where a wall would be in the way. The size of posts and beams is determined by how much weight they have to support and calculated by an architect or engineer. Posts and beams can be steel, wood or engineered lumber.

On-Center

When placing joists, studs, rafters or trusses, carpenters need to know how far apart to install them. The distance is indicated on building plans and is commonly referred to as “on-center” measurement. Joists placed 16 inches on-center will have 16 in. from the center of one to the center of the next. For ease of measuring and marking, carpenters measure from the edges rather than centers of the framing members. This works as long as you measure from left edge to left edge or right edge to right edge.

*The term “member” is used to describe virtually any object that’s part of a greater assembly or structure. Carpenters often use member to generally describe any part of a house frame within a certain category. For example, you might hear a builder say “The roof frame members are stacked over there.”

Floor Joist

Floor joists are the framing members that support the floor and walls above them. They run horizontally and are usually spaced 12, 16 or 24 inches on-center. They are supported by the foundation or posts and beams and sized according to how much weight they support. Traditional wood joists are usually 2×8, 2×10 or 2×12 lumber, but modern houses often use engineered joists like trusses or I-joists because they provide better strength for less cost.

Rim Joist

A floor frame consists of framing members that rest on posts, beams or foundation walls. Rim joists are the parts of the floor frame running perpendicular to the floor joists and enclose the ends of the floor joist assembly holding the joists in position. Carpenters cut the rim joists to length and mark the location of the joists on them. Then the joists are cut to length, aligned with the marks on the rim joists and nailed through the rim joists into the ends of the joists.

Blocking

Short lengths of wood or engineered lumber that are cut to fit between joists, studs or trusses are called blocking. Blocking is installed for a variety of reasons. Structural blocking is indicated on the house plan and provides extra strength. Fire blocking prevents the spread of fire inside an enclosed floor, wall or ceiling. Some blocking is also installed to provide a solid attachment for handrails, grab bars or other hardware.

Subfloor

Nailed or screwed to the top of the floor joists, the subfloor provides a platform for the walls above and a base for the finished floor materials. Subflooring is usually 5/8 to 3/4 inches thick and available in 4×8-foot sheets. Plywood and OSB (oriented strand board) are the most common materials used for subfloors.

Wall Plate

Plates are the horizontal members that are found at the top and bottom of walls and function to hold the wall studs in position. They are usually the same width and material as the studs. Carpenters cut the plates to length and mark the position of doors, windows and studs on them as a guide for building the walls. Standard construction includes a bottom plate, top plate and a second top plate overlapping the adjoining wall tying the walls together.

Stud

Studs are the vertical members that, together with the plates, make up the wall frames. They are usually 2x4s or 2x6s spaced 16 or 24 inches on-center and can be standard framing lumber or engineered lumber, like laminated strand lumber. To save time, carpenters often buy precut studs available in 92-5/8, 104-5/8, and 116-5/8 inch lengths to build standard 8-, 9- and 10-foot-tall walls. Studs that don’t extend from the bottom plate to the top plate have special names.

Trimmer or Jack Stud

Window and door openings in walls require a horizontal framing member across the top of the opening. The studs that run vertically along the sides of window and door openings and are cut to fit from the bottom plate to the underside of this horizontal member are called trimmers or jack studs.

King Stud

Window and door openings in walls also require a vertical framing member lumber (left and right) of a window or door opening that runs continuously from the bottom sole plate to the top plate.

Cripples or Cripple Stud

Studs cut short to fit below or above window and door openings are called cripples. When carpenters mark the plates for stud locations they indicate the location of cripples with a special mark to show that these are not full-length studs.

Header

Headers are little beams placed above window and door openings to support the weight above. The wider the opening, the stronger the header has to be. Headers can be built up by layering standard 1-1/2-inch-thick framing lumber, or they can be engineered lumber. The ends of headers are supported by trimmer studs.

Load-bearing Wall

A wall required to support the weight above it is referred to as a load-bearing wall. Exterior walls are almost always load bearing because they support the floors above as well as the roof. Some interior walls are also load bearing. When remodeling, removal of a load-bearing wall requires adding a beam to carry the load.

Stringer

Stairs have all kinds of parts including treads, risers and railings. Installing these is usually the job of a finish carpenter. But the framing carpenter is responsible for cutting and installing the stringers. Stringers are the angled stair supports running from the ground to the main floor or from floor to floor. Stairs require at least two stringers, but usually three or four depending on how wide the stairway is. Stringers are typically notched to provide a level surface for the stair treads and a vertical surface for nailing on the riser boards.

Wall Sheathing

Wall sheathing is applied to the outside of the wall framing to enclose the structure. Depending on the type of sheathing, it can also provide bracing, insulation or a nailing surface for siding materials. Sheets of plywood, OSB, gypsum and extruded polystyrene are a few common types of sheathing material.

Rafter

Rafters are the angled framing members that make up the roof structure. Roofing sheathing and the roofing materials are placed over and on top of the rafters. There are several types of rafters named for their location and function in the roof frame. These include common, hip, ridge, valley and jack rafters. Rafters are sized according to the weight they must support and the distance they span. They are usually spaced 16 or 24 inches on-center to line up with a standard 4×8 sheet of roof sheathing.

Roof Slope

The slope of a roof is a common term used by architects and builders to describe a roof’s incline, or how steep it is. Carpenters also use roof slope to cut the ends of rafters to the correct angle. Slope is specified with two numbers indicating the rise and run. The first number, the rise, tells the vertical distance the roof rises for every foot of run. The second number, the run, is always 12 inches. A roof with a 3:12 pitch would be fairly flat while a roof with a 12:12 pitch would be very steep.

Roof Truss

Cutting and assembling rafters requires a skillful carpenter and a fair amount of time. To simplify the job and save time and money, engineers developed roof trusses to replace rafter assemblies. Roof trusses are designed and built in a factory to match the roof slope, dimensions and style of the house. They are then delivered to the job site where they’re intstalled according to a roof plan provided by the manufacturer. Trusses are usually spaced 24 inches on-center to align with standard sheets of roof sheathing.

Roof Sheathing

Roof sheathing is typically 7/16, 1/2 or 5/8 inch thick and available in 4×8-foot sheets. Plywood and OSB are common sheathing materials. The sheathing is nailed to the top of rafters or trusses providing a base for the installation of roofing materials.

Floor Truss

Floor trusses are built with 2x4s or 2x3s with a wide, stable surface that is easier to work on and around. They were designed to replace a standard floor joist made of dimensional lumber. They eliminate the need for additional beams to support a floor because of their stiffness and strength. Their wide nailing surface provides a surface for easy gluing and quick, accurate attachment of sheathing and subfloor. This helps reduce squeaks. They also leave plenty of room for plumbing, electrical and mechanical runs.